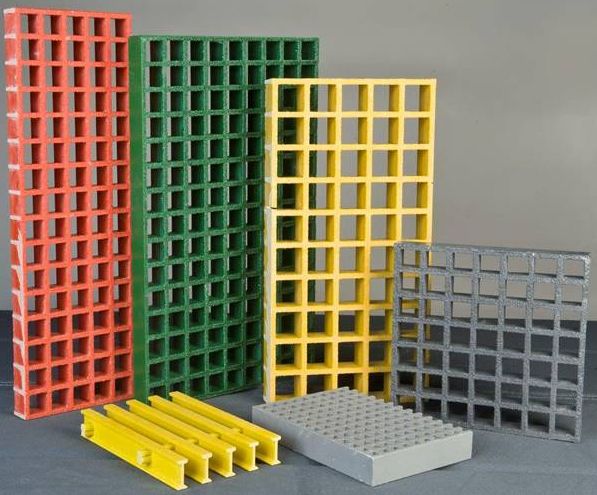

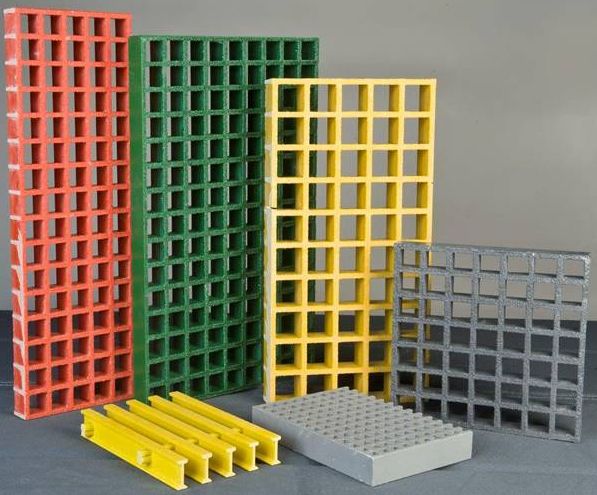

Customisable to Your Need

We offer fully customisable FRP grating to suit your project’s specific requirements, including custom sizes, designs, and colours.

Customisable FRP Grating for Walkways and Pathways

Reinforce Tech’s FRP (Fibre Reinforced Polymer) grating offers a lightweight, corrosion-resistant, and anti-slip solution for a variety of applications, including power station walkways and rooftop Solar systems.

Durable and Impact Resistant

Our FRP grating is designed to absorb high energy and can withstand repeated impacts without permanent damage. Unlike steel, which can buckle under impact (such as from a forklift), our grating maintains its integrity, providing long-lasting durability.

Behaviour Under Repeated Use

In access environments subject to repeated foot traffic and incidental impacts, material behaviour over time must be considered. FRP grating is typically assessed where resistance to corrosion-related degradation and surface damage supports predictable long-term use, subject to application-specific loading and verification.

FRP grating is typically assessed where resistance to corrosion-related degradation and surface damage supports predictable long-term use, subject to application-specific loading, specification, and verification.

FRP Grating for Walkways and Pathways

Project-Specific Configuration

Panel size, thickness, surface profile, colour, and edge treatment can be configured to suit project-specific requirements following application context and specification review.

In industrial and infrastructure environments, access systems are exposed to corrosion, moisture, chemicals, and repeated loading.

Over time, traditional steel walkways degrade, increasing slip risk, inspection burden, and long-term maintenance cost.

FRP Grating & Walkways Designed for Safe Access in Degrading Environments

Slip Resistance Is a Lifecycle Issue

Slip resistance is not a one-time specification.

In aggressive environments, coatings wear, corrosion develops, and surface conditions change over time.

FRP grating is typically selected where inherent surface profiles can support slip resistance requirements, with performance assessed and validated through application-specific specification and testing rather than reliance on applied finishes alone.

Where FRP Grating Is Typically Selected

Corrosive or chemically aggressive environments

Wet or frequently washed-down areas

Electrically sensitive locations

Access routes requiring reduced maintenance intervention

Appropriate Use and Limitations

FRP grating is not a universal replacement for steel. Load requirements, span conditions, fire performance criteria, and regulatory context must be assessed during specification to determine suitability for the intended application.

FRP Grating